Quite a nice long update today after a bit of a lull.

Well the engine has now been run and in and setup on the dynamometer. The firing order had to be changed to 351 spec rather than 302 as I had it. The timing was set and a few setup changes on that too but the carburettor was pretty much spot on.

Peter and Knight Racing did the testing and seems happy with what I have built which is very satisfying. The results are as below.

I must say that I am really pleased with the result. More or less 450 bhp and 426 ft/lb should be adequate....

Now it needs attaching to the gearbox etc and finally fitting into the chassis.

So, onto the next task.

First thing I did was to attach the flywheel. At this point I can dial in the bell-housing to make sure the input shaft of the gearbox is less than 0.005" runout. Initially when I set it up to measure the runout it was about 0.018" out in the worse case. Now, after selection and fitting a set of offset dowels it is very much closer and fully within tolerance.

|

| All dialled in. |

|

| 0.007" offset dowels from Stateside Autos of Nuneaton. |

So now I can go ahead and fit the clutch assembly not forgetting to very closely follow all assembly instructions and final torque settings. I have chosen to fit a McCloud twin plate clutch with hydraulically actuated lever arm.

|

| Back-plate, flywheel and first part of clutch |

|

| Fully fitted clutch |

|

| Pivot installed |

|

| Bell housing fitted although I have forgotten to add the actuator bracket! |

|

| Clutch release lever and bearing fitted |

At this point my patience was somewhat tried. Could I get the gearbox to engage through both plates! Oh no. No chance. I had spent a lot of time making sure that all was very carefully centred and that I didn't push on the pressure plate springs when trying to fit the gearbox (which I must have done as the back plate moved.... again). In the end I gave up for the night, had a cup of coffee and relaxed only to begin battle tomorrow.

|

| Just about to lift the and align the gearbox |

|

| Finally fitted after much effort and frustration |

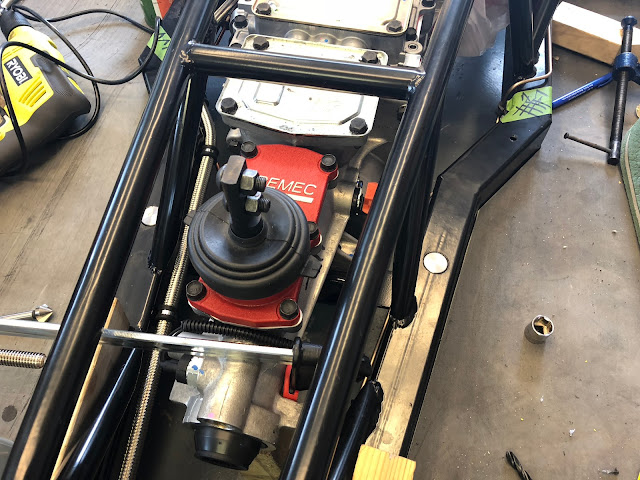

I ended up making some dowels out of long bolts so that I could slide the gearbox along these keeping it level and central. There were two of us doing this in the end and with Pete's help and the thought "why not depress the clutch lever, I have nothing to loose!!" it slide on so smoothly and we were able to bolt it up permanently. Boy, that was a relief to get that done. I was all ready to call it a day but Pete had come over specifically to help me get the engine/gearbox assembly into the chassis so we persevered.

|

| In the air and removing the engine frame |

|

| Nearly in. Lots of gently manoeuvring back and forward and up and down |

|

| Nearly there although there is a clash with the fuel pump and I squashed the brake pipe. Oh well can't be helped. |

|

| Fuel pump and brake pipe issue. Needs to be sorted. |

|

| And there it is in its final position along with make shift gearbox mounts. |

Finally in and fitted. Thanks Pete, couldn't have done it without you.